SU INSTALLATION INSTRUCTIONS

GENERAL

- Mount the phasing unit in an upright position

at a location convenient to the motor and magnetic starting control.

- Check all connections to make certain that

none have been jarred loose during shipment. Make certain that all

coil jumper connections are tight.

CONNECTIONS

Some of the leads have been tied together inside

the unit at the factory. Do not disconnect these leads.

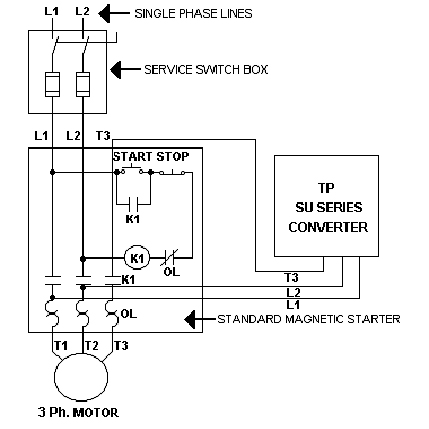

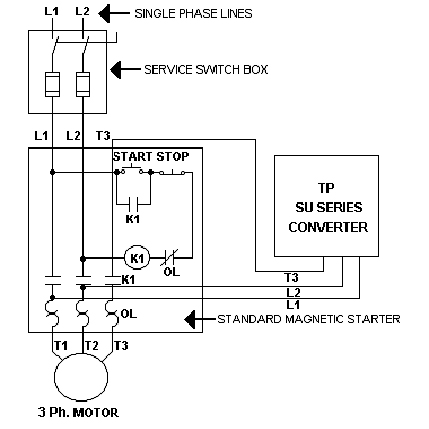

- The lead marked L1 in the converter will be

connected to L1 on the starter between the contacts and the overload heater.

- The lead marked L2 in the converter will be

connected to L2 on the starter between the contacts and the overload heater.

- The lead marked T3 in the converter will be

connected to L3 on the line side of the starter ahead of both the contacts

and the overload heaters. All three connections are made inside the

standard magnetic motor control box.

- Double check the connections.

It is extremely important that a thermal overload

lead be connected in the T3 line in order to protect the motor in

case the starting relay fails to operate properly or the motor experiences a

severe overload or a complete stall.

CIRCUIT BALANCING

If the motor and phasing unit are checked while

operating with no load, current in the T3 line will be as high or

higher than full rated current. This is a normal condition, as the current

is capacitive and will decrease as the motor load increases. Should the T3 current exceed full load current of the motor by more that 5%,

one of the rectangular running capacitors may be removed from the circuit by

disconnecting one lead from the top capacitor. This will reduce the T3 current. When the phasing unit and motor have been

installed and connected following these instructions, the manufacturer is

confident that performance will be more than satisfactory. Perfect

symmetrical balance in phase currents and voltages will not be present as in

true three phase operations; however, at full rated load, the TP Phasing unit

allows for a near balanced condition.

Follow the diagram above when

installing the TP phasing unit. The T3 line must be connected ahead of the

thermal overload on the line side of the contact. The leads marked L1 and

L2 are connected to the two energized phases of the contactor above the thermal

overload relays.

RT INSTALLATION INSTRUCTIONS

GENERAL

- Do not undersize your wire.

- Consult your utility company as to the size

and type of service entrance equipment that you will need. The

transformer which they provide must be large enough to supply the total

three phase load, single phase load, the occasional overload and converter.

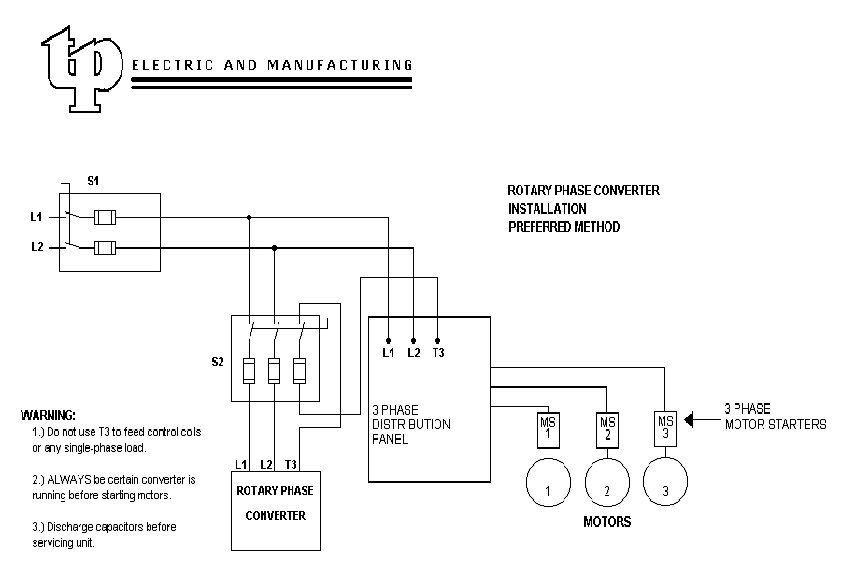

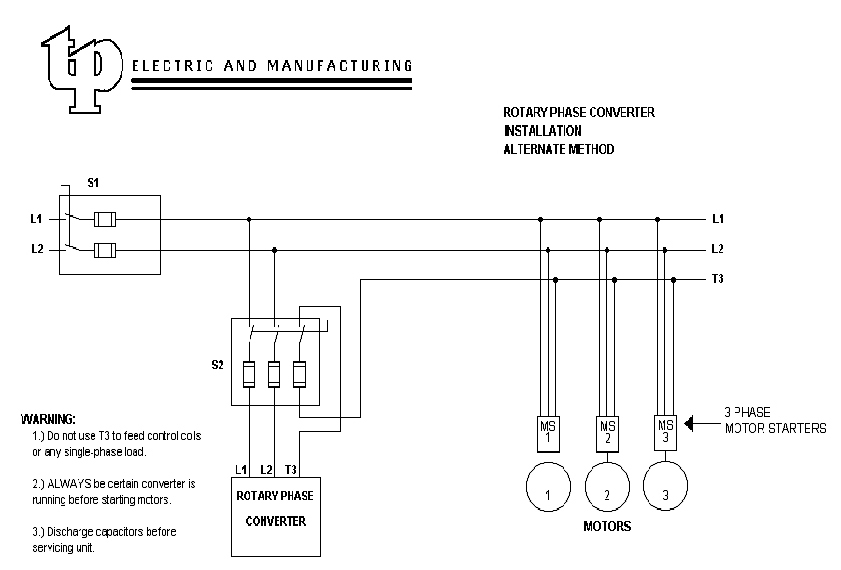

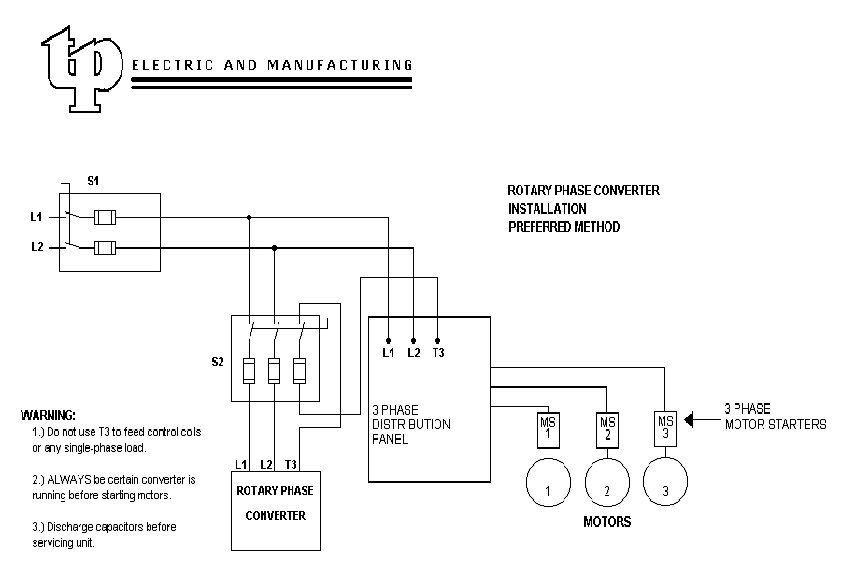

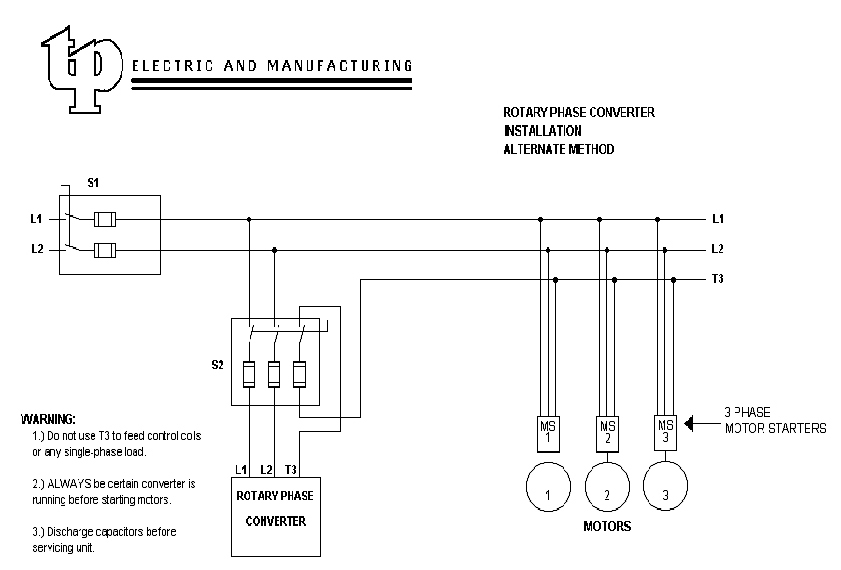

- We prefer that you install the converter

indoors but this is not always possible. Many of our converters have

been running for years outside, however, a little shelter will greatly

increase the operating life.

- Use a safety switch or magnetic starter after

the main disconnect to start the converter.

- It is possible to up rate the converter by

using the power packs. Consult the factory for further information.

CONNECTIONS

- Connect L1 of the single phase power to L1 in

the junction box of the converter.

- Connect L2 of the single phase power to L2 in

the junction box of the converter.

- T3 is the manufactured phase and should be

color coded. The phase is not to be used for control coils, lights or

any other single phase load.

- The phase currents may fluctuate when other

motors are started and stopped. It is sometimes necessary to use the

next size larger heater coils.

- When the converter is running two motors, each

at the maximum horsepower rating, it is likely that one will require a power

pack. A power pack is an additional capacitor bank. The power

pack must always be applied at the load side of the starter so that it will

be energized only when that motor is operating. One lead from the

power pack connects with load terminal L2 and the other lead connects ahead

of the heater element to load terminal T3. Failure to install the

power pack correctly could damage the converter.

- Ground the converter frame.

OPERATING

- Line voltage must be within 10% of the voltage

rating of the converter (230VAC or 460VAC). Under no-load conditions

the manufactured T3 phase voltage may be 25% above the input voltage.

Under full load the manufactured T3 phase voltage may be 15% lower than the

input voltage.

- Always allows the converter to reach full

operating speed before starting any motors.

- Starting loads should not exceed the nameplate

rating of the converter. Smaller motors may be started together if the

total horsepower does not exceed the nameplate rating.

SERVICE

Very little service is required to maintain

the converter. Each bearing should be lubricated every 90 days with 1/4

ounce of Chevron Type SR1 or equivalent.

TROUBLESHOOTING

The converter will not start.

-

Check for low single phase line

voltage.

-

Check fuses.

-

Check the installation steps

again.

-

Check for a shorted oil

capacitor.

-

Check bearings.

-

Check for a damaged winding.

The load motor will not start.

-

Check for low single phase line

voltage.

-

Motor could be faulty.

-

Motor could be overloaded.

-

Check heaters.

-

Check for voltage drop.

Phase currents are greatly

unbalanced.

-

Check for low single phase line

voltage.

-

Converter may be overloaded.

-

A power pack my be required.

The converter or motor runs hot.

-

Check bearings.

-

Check for a damaged winding.

-

Make sure that the power pack is

properly connected.

-

There may be insufficient load

on the converter.

Full

Size

Full

Size

![]()